Industrial Safety sensors

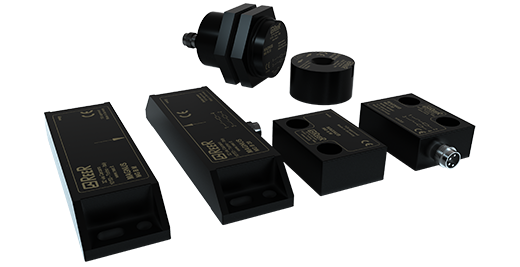

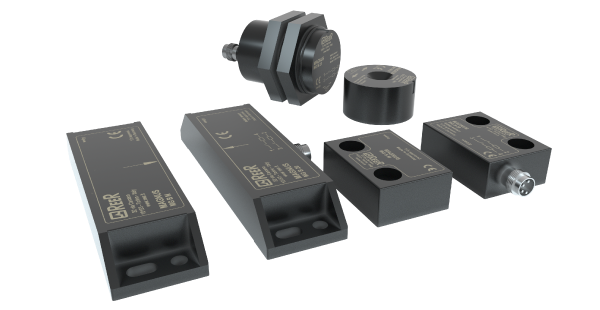

Contactless sensors – Magnetic, Inductive and RFID safety switches for position control of movable guards. The Contactless safety sensors are used to monitor the position of the safety devices sliding, hinged or removable.

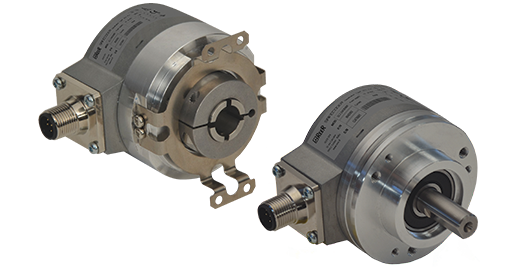

Safety encoders – Safety Sin/Cos incremental encoder for any applications requiring speed monitoring of a rotating axis.

Safety interlock switch with guard door locking – Mechanical, electrical or other type of safety device, the purpose of which is to prevent the operation of hazardous machine functions under specified conditions (generally as long as a guard is not closed).

Laser scanner – AOPDDRs (Active Opto-electronic Protective Device responsive to Diffuse Reflection) measures the distance between the objects that fall into its sensing field by means of the small fraction of energy that is re-diffused by the objects themselves in axis with the direction of emission. AOPDDRs do not need a cooperating target for their operation, especially where the protected area is mobile, as is the case with AGVs, or where it is necessary to vary the position and size of the protected area during the production process.

Main characteristics

SAFETY LEVEL

Defines the self-monitoring and safety principles contained in the device; it must be chosen as a function of the risk level characterising the machine.

RFID

Radio-frequency identification (RFID) uses electromagnetic fields to automatically identify and track tags attached to objects. An RFID system consists of a tiny radio transponder, a radio receiver and transmitter.

TYPE OF ENCODING

- Individual coding: the actuator is programmed via teach-in and permanently assigned to the sensor during set-up (the process can be repeated if necessary)

- Unique coding: the actuator is permanently assigned to the sensor during manufacturing (it cannot be replaced with another actuator)

- Actuator coded: the actuator is free and not specifically assigned to the sensor (one actuator can work with multiple sensors)

SWITCHING DISTANCE

The outputs (OSSD) are only enabled when a damping target is present in the enable zone. Outside this enable zone the outputs remain switched off.

Discover our safety devices

TECHNOLOGY

Magnetic

RFID

Proximity inductive

Photocells

Interlock

Encoder

TECHNOLOGY

Magnetic

RFID

Proximity inductive

Photocells

Interlock

Encoder

TECHNOLOGY

Magnetic

RFID

Proximity inductive

Photocells

Interlock

Encoder

TECHNOLOGY

Magnetic

RFID

Proximity inductive

Photocells

Interlock

Encoder

Contactless

Series connections

Contactless

Series connections

Contactless

Series connections

Contactless

Series connections

CONTROL UNIT

Mosaic

MZERO

SR ONE

SR SELELCT

SR X/XM

Mosaic MVx

CONTROL UNIT

Mosaic

MZERO

SR ONE

SR SELELCT

SR X/XM

Mosaic MVx

CONTROL UNIT

Mosaic

MZERO

SR ONE

SR SELELCT

SR X/XM

Mosaic MVx

CONTROL UNIT

Mosaic

MZERO

SR ONE

SR SELELCT

SR X/XM

Mosaic MVx

SAFETY LEVEL Type 4 - PL e - SIL 3 - | IP RATING IP65 IP67 IP69K |

SAFETY LEVEL PL d / PL e | IP RATING IP65 IP67 IP69K |

SAFETY LEVEL Type 4 - PL e - SIL 3 - | IP RATING IP65 IP67 IP69K |

SAFETY LEVEL Type 4 - PL e - SIL 3 - | IP RATING IP65 IP67 IP69K |

| FIELD-BUS CONNECTION | Through Mosaic |

|---|---|

| INTERAXIS | 22 mm |

| FIELD-BUS CONNECTION | Through Mosaic |

|---|---|

| INTERAXIS | 22, 78 mm |

| FIELD-BUS CONNECTION | Through Mosaic |

|---|

简体中文

简体中文