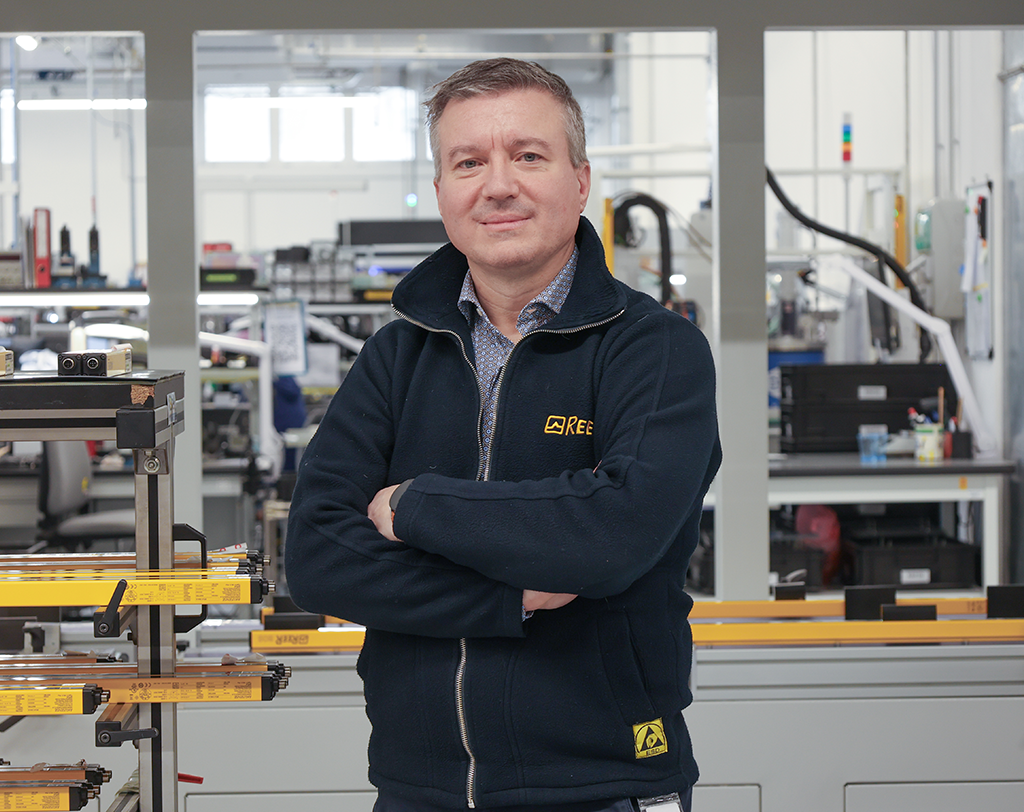

Can you tell us something about your professional background before joining ReeR Safety?

I am an aerospace engineer specialising in aeronautical structures. My career has led me to work in very different sectors, but all of them share a high level of technological complexity. I started in the automotive industry, working on the production of engines and gearboxes, and then moved on to the railway industry with the development of high-speed trains. I also gained experience in the aerospace sector, in the construction of engines and turbines, and later in industrial automation and robotics, where I focused on the production of automated robotic lines. Finally, I had the opportunity to work in the rubber and plastics sector, overseeing the production of tyres for the automotive industry.

In all these areas, I held positions of increasing responsibility, starting as a Field Engineer and moving through maintenance to become Factory Engineering Manager and Production Operations Director. This varied career path has allowed me to develop a comprehensive and cross-functional view of production processes, from the design phase to strategic management, and it is precisely this background that I bring to ReeR Safety today.

What prompted you to accept this new challenge in the industrial safety sector?

Industrial automation is constantly growing, and with it the need to make robotic systems and lines increasingly safe. Unfortunately, we still too often read news stories about accidents at work caused by the absence of safety devices or the insufficient reliability of existing ones. It was precisely this awareness that prompted me to want to make a concrete contribution to a sector that I consider fundamental for the future of industry.

Industrial safety is not a minor detail: it is the basis for ensuring sustainable productivity and protecting people. I have always been fascinated by electronics, and behind every device like those we develop at ReeR Safety, there is a precise, accurate and organised mechanism, the result of rigorous collective work. These are all characteristics that I identify with and that convinced me to accept this challenge.

What was your first impression when you entered the ReeR Safety production department?

The first time I entered the production department, I immediately had a positive impression. In the past, I worked in industries where order and cleanliness were goals to be pursued daily with great effort and continuous attention. At ReeR Safety, however, I found a reality where this culture was already ingrained in people.

From the cleanliness of the workbenches to the floors, everything conveys discipline and responsibility. Upon entering, it almost feels like stepping into a clean room, where every detail is taken care of and where there is a clear awareness that a tidy and clean environment is not just a matter of aesthetics, but a fundamental value for those who manufacture devices designed to ensure safety in industrial plants around the world.

What are the most interesting challenges you have encountered so far in production management?

I found a well-organised department that was already structured according to Lean Manufacturing principles, with production flows recently redesigned to improve efficiency. The most stimulating challenge I am facing concerns logistics, both inbound and outbound.

Inbound and outbound logistics are two key issues for an international supply chain like ours. Working on optimising incoming raw materials and managing shipments to customers allows us not only to reduce delivery times, but also to lower costs and improve inventory management. Every step forward in this direction has a direct impact on ReeR Safety’s competitiveness and on the satisfaction of our customers in Italy and abroad.

What role does the production team play in ReeR Safety’s success?

The production team is the beating heart of our company. I like to compare it to the mast of a ship: without it, there would be no way to sail and reach new destinations. The more solid it is, the more it is able to withstand the force of the winds, which for us are the demands of the market, which are increasingly demanding and variable.

The strength of our production department lies in discipline, team spirit and the responsibility that each person brings with them every day. It is this solidity that allows ReeR Safety to guarantee reliable, safe and high-quality Italian products that are recognised and appreciated internationally.

What does manufacturing in Italy mean to you, for a company that exports all over the world?

Manufacturing in Italy is a source of great pride. Italy is universally recognised as synonymous with quality, design, innovation and manufacturing tradition. Bringing industrial safety devices manufactured in our Turin plant to international markets means not only guaranteeing a technologically advanced product, but also conveying the values of Made in Italy.

Every device we produce embodies the passion and expertise of people who work with dedication, aware that they represent Italian excellence in a sector as sensitive and strategic as industrial automation safety.

How does ReeR Safety combine Italian manufacturing tradition with technological innovation?

Italian manufacturing tradition has always stood out for its attention to detail and craftsmanship. At ReeR Safety, this cultural heritage coexists with the latest technologies, creating a combination that makes us competitive and unique.

We have introduced rapid prototyping systems through 3D printing, implemented artificial vision technologies for testing and adopted sustainability solutions such as photovoltaic systems and an advanced energy management system. In addition, we have developed complete traceability of our product components, so that we can guarantee transparency and rapid response to customers.

All this is possible without distorting our identity. On the contrary, innovation has become an ally of tradition, allowing us to enhance it and project it into the future.

How do you envision the future of industrial production in the safety sector?

The future will be characterised by continuous growth in demand for industrial safety devices. Advanced automation will increasingly replace manual tasks performed by humans, making it essential to ensure safe coexistence between operators and machines.

I believe we will see more and more intelligent and interconnected products that can be integrated into the digitised processes of the factories of the future. Our mission will be to accompany this change by providing solutions that not only meet regulatory requirements but also become an integral part of industrial productivity and sustainability.

Which company departments does your team work with?

Certainly, our primary contact is the production department, particularly the colleagues responsible for testing equipment. We also collaborate with the purchasing department, after-sales, quality control, and sales. Due to the technical nature of ReeR, much of the company revolves around the technical department.

What message would you like to convey to ReeR Safety’s customers and partners?

The message I want to convey is simple: at ReeR Safety, we deliver on our promises. Our values are not just words, but concrete actions that are reflected in our products, our processes and the way we work with our customers and partners.

Anyone who wants to get to know us better is welcome to visit our factory. Only then can you truly appreciate how much teamwork, passion and care goes into every industrial safety device that bears the ReeR Safety name.

简体中文

简体中文